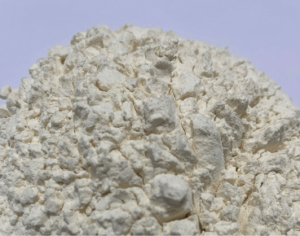

Adhesive Grade Modified Starch for Tube Core & Metallurgical Applications

Adhesive Grade Modified Starch for Paper Tube Core

60–120 sec viscosity

Moisture 3–5%

pH 5.5–9

Strong initial tack

Smooth application

Ready stock in Bengaluru & Mangaluru

Custom viscosity grades for OEMs

High reliability for fast-speed processes

Technical support for adhesive preparation